Automobile Zhongwang mould

keywords: About Us、Culture、Development、Organizational、

Taizhou Huangyan dinggu mould factory is located in Huangyan, Taizhou, Zhejiang Province, the hometown of plastic molds in China. The company is a mold company specializing in the design and manufacture of automobile and electric vehicle molds. The company is mainly composed of skilled and experienced professionals, focusing on the design and manufacture of precision molds, familiar with various precision mold structures and design specifications, and providing high-quality, efficient and low-cost services, With scientific and standardized management means to provide customers with efficient and high-quality services, it is your best partner to occupy the market, create opportunities and improve competitiveness. The company takes "perfect quality and perfect service" as its concept and "to help you create a corporate brand" as its own mission. We are willing to sincerely cooperate with friends from all walks of life, go hand in hand and develop together.

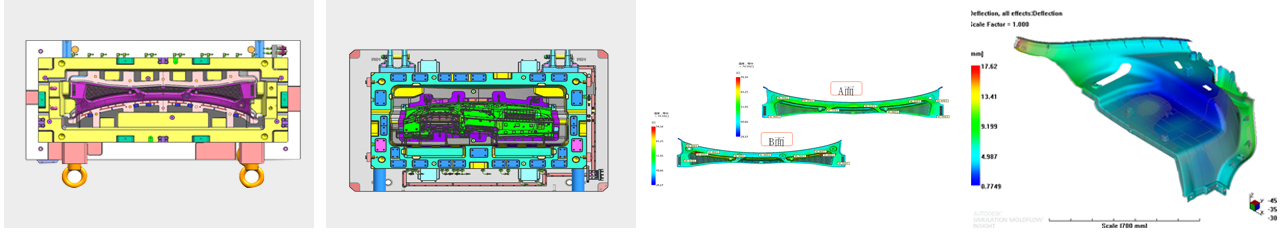

1、Mold structure of automobile plastic parts

Dinggu mold plastic is a famous plastic mold manufacturing enterprise, specializing in the production of various high-efficiency, difficult, high-precision plastic molds. It is not only a professional plastic mold manufacturer, but also an injection mold factory that provides complete solutions for the plastic molding industry.

With excellent injection mold solution services, we will provide high-quality and fast services to customers all over the world! Sincere cooperation, welcome to contact us at any time. We will give you a reasonable solution to solve the problem at the first time.

2、Mold design of automobile plastic parts

The core of mold life! Good mold structure design is the premise of qualified mold manufacturing. Our mold designers and stylists have more than 10 years of professional mold design and manufacturing experience, and can comprehensively analyze the mold structure and product structure (including mold flow analysis, mold demoulding slope, product surface miniaturization, gating system design, gas system design, cooling system design). The most important and easiest problems of these molds will be tested repeatedly during mold structure design.

Customize fine mold structure for customers to meet customer module requirements

Molds provide knowledge and experience to share and discuss with customers, put forward cutting-edge technological concepts, and participate in customer product design. We will timely deliver product structure design, product mold manufacturability, mold drawings and 3D to customers, so that customers can intuitively inform customers of product design ideas, mold manufacturing ideas, work side by side with customers, and avoid development risks.

3、Automobile plastic mold manufacturing equipment

4、Maintenance of automobile plastic mold

The more important the mold maintenance is, the more the mold maintenance times are, and the shorter the service life is; The better the mold is maintained, the longer its service life will be. Mold maintenance is mainly divided into three points:

1、Daily maintenance: thimble, alignment, guide post, guide sleeve oil, mold surface cleaning, drainage and other moving parts, which is the daily maintenance of mold production.

2、Regular maintenance: regular maintenance includes cleaning the exhaust slot, adding exhaust gas at the blackened position, and correcting damaged and worn parts.

3、Appearance maintenance: paint the outside of the mold to avoid rust. When lowering the mold, the fixed mold and the moving mold should be coated with antirust oil. The mold should be closed tightly to prevent dust from entering the cavity.

5、 After sales service of automobile plastic mold

1: Respond in time (within 1~10 hours)

2: each stage of production has a perfect quality control system;

3: Competitive price and good quality;

4: advanced project tracking system, on-time delivery (4-7 weeks);

5: Rich experience in mold export overseas market

6、 Dinggu mold manufacturing culture

Dinggu mold has unique mold manufacturing culture. We believe that if we do everything according to our responsibilities, everything will be done well. Therefore, our mold manufacturing core culture is responsibility.

Dinggu mold has many key points, all of which must be done well in the mold manufacturing process. Actions include:

1. Customer inquiries before mold manufacturing.

In this process, the communicators of both parties shall provide correct information or specifications to ensure that the pricing and technical points meet the requirements of the buyer.

2. In the manufacturing process, designers need to be responsible for mold design. This responsibility is not only for the customer, but also for the company. He should consider how the customer uses the mold, how to design long-life tools for the mold, and how to design relevant parts to make the mold processing easier and more accurate in the mold manufacturing process.

3. Mold parts processing in mold manufacturing process.

The machine operator has a strong sense of responsibility, so the mold parts can be accurate enough to meet the tolerance requirements of the drawing. Here, careful die structure installation, strict processing process compliance and strict dimensional control during and after processing show responsibility.

4. Dimension control of die parts after machining. In the manufacturing process, the cavity, core and other mold components need strict dimensional control after processing. The cam team is responsible for ensuring that all dimensions are consistent with the drawings.

As well as the mold assembly workshop and the mold mass production simulation workshop, they all need to be responsible to ensure that the mold manufacturing is successful and the delivered mold meets the Hongmei mold standard.

7、 Why do you choose us to manufacture automobile plastic molds

1. Good quality

2. On time delivery

3. Competitive price

4. Excellent after-sales service

5. Professional communication with customers in the mold process

6. We can provide a full set of injection molding production lines

7. Analog flow analysis software

We always focus on the perfection of quality and service. We are willing to provide good service and excellent products for all customers.

If you are interested in our company, please feel free to contact us by phone, email or instant chat software. You are always welcome to visit our company.

Let's start cooperation and create mutual benefit for each other as soon as possible!

Contact Us

13306555707

Tel:

13306555707

Fax:

0576-84022708

Email:

zhangxiaojun@tzdinggu.cn